Industrial Scouring Pads

- Product Information

Industrial Scouring Pads is a cleaning and surface treatment tool designed for industrial scenarios. Its core function is to remove dirt, oxide layers, coatings or burrs on the surfaces of metals, wood, plastics, etc. through physical friction. It is also suitable for precision polishing, deburring and other processes. Compared with civilian scouring pads, the fiber density of Industrial Scouring Pads is increased by 300%, the temperature range is extended to -40℃ to 150℃, and the life is extended by 5-8 times. It is a core consumable in the manufacturing, construction and maintenance fields.

Industrial Scouring Pads Parameters:

| Model Number: | SC-345 |

| Product name: | Heavy duty scouring pad |

| Color: | Green |

| Characteristic: | Easy hold |

| Material: | Polyester,Resin,Abrasive |

| Finish : | Customized |

| Application: | Kitchen cleaning and dish washing |

| Design Style : | Modern |

| Place of Origin: | Guangdong,China |

| MOQ: | 20000 Sets |

| Package: | Wrap card or polybag per set |

| Delivery time: | About 30 days |

| Sample: | Available |

Features of Industrial Scouring Pads

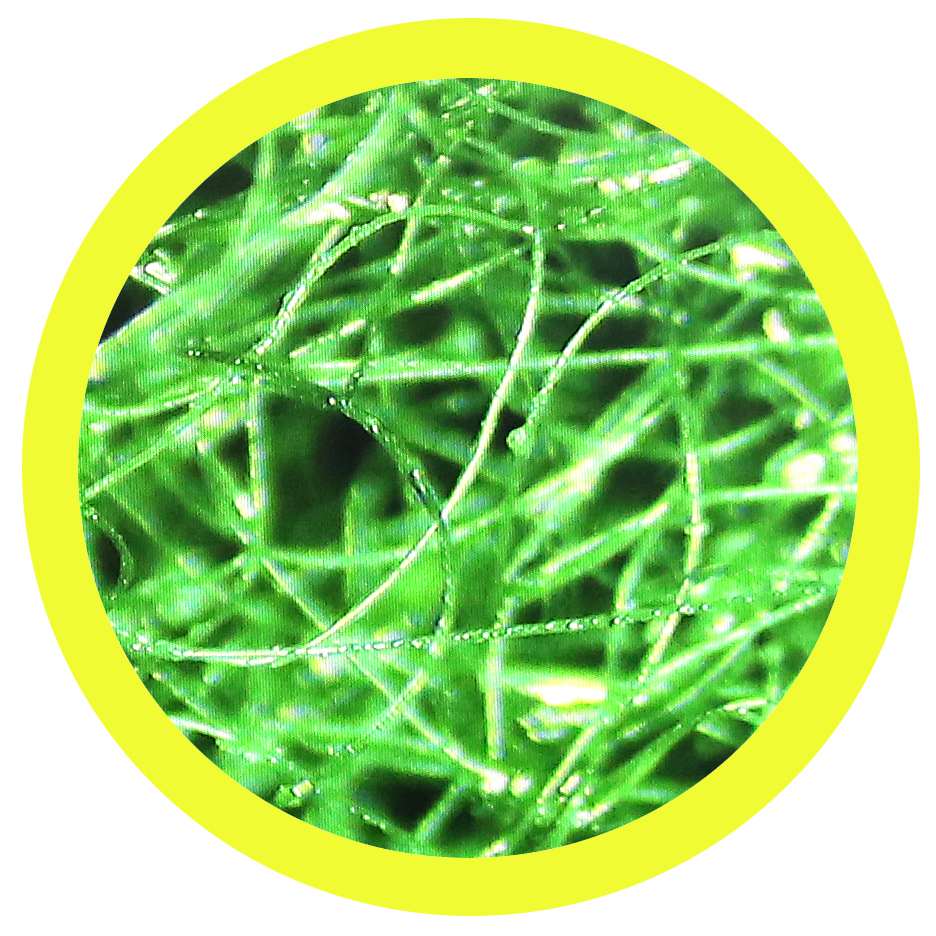

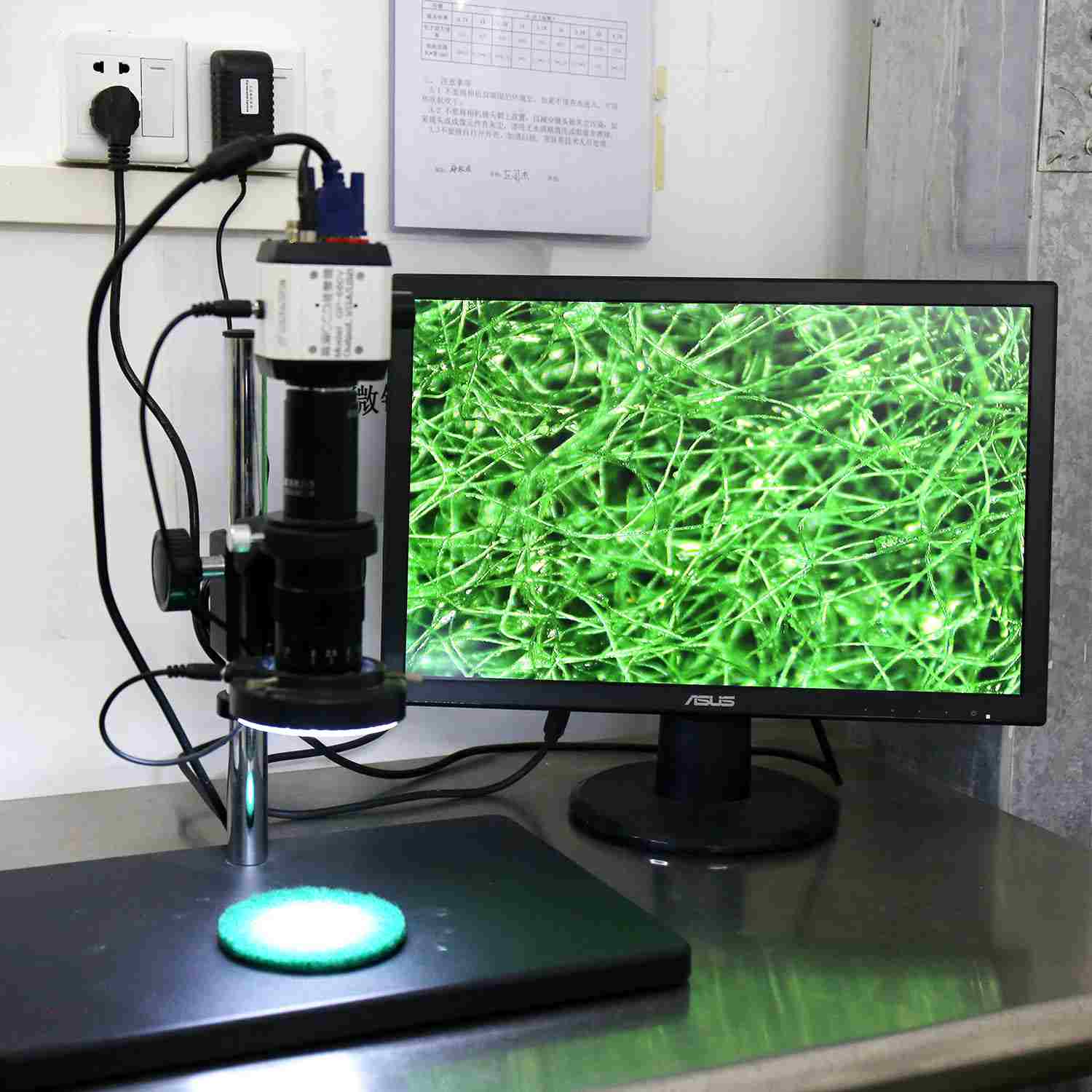

1. Non-woven fabric substrate

Using polyester fiber, nylon or carbon fiber composite materials, the fiber diameter is 50-100μm, the tensile strength is ≥150N/cm², and the wear resistance is increased by 400%.

2. Bonding process

Through hot melt adhesive or epoxy resin compounding, the peel strength is ≥20N/cm, ensuring the firm bonding of the fiber layer and the substrate and reducing the risk of chipping.

3. Temperature range

-40℃ to 150℃, suitable for extreme industrial environments (such as high temperature welding, low temperature freezing).

4. Chemical resistance

Can withstand solutions with acid and alkali concentrations ≤10% (such as hydrochloric acid, sodium hydroxide), and corrosion resistance time ≥24 hours.

5. Friction coefficient

Dynamic friction coefficient 0.6-0.8, static friction coefficient 0.8-1.0, providing efficient cleaning power.

Specifications and customization

6. Anti-static treatment

Surface resistance ≤10⁹Ω, reducing industrial dust adsorption and reducing explosion risks.

Application scenarios of Industrial Scouring Pads

1. Metal processing industry

Deburring and polishing: used for deburring of stainless steel and aluminum alloy parts, surface roughness Ra ≤0.8μm, improving product aesthetics.

Weld cleaning: remove welding oxide layer, efficiency is 3 times higher than traditional sandpaper, reducing secondary pollution.

2. Shipbuilding and heavy industry

Hull rust removal: with high-pressure water gun, remove hull rust layer, speed up to 0.5m²/min, extending coating life.

Engine maintenance: clean the oil stains on the engine cylinder, with a decontamination rate of ≥98%, reducing the amount of detergent used.

3. Construction and decoration

Concrete surface treatment: remove template residues, surface flatness ≤2mm/m, and improve paint adhesion.

Stone polishing: used for rough grinding of marble and granite, with an efficiency 50% higher than traditional grinding discs.

4. Food processing industry

Equipment cleaning: clean the oil stains on equipment such as ovens and fryers, with a temperature resistance of 150℃, no fiber residue, and in line with HACCP standards.

Pipeline descaling: remove biofilm on the inner wall of the pipeline, with a sterilization rate of ≥99%, reducing cross contamination.

5. Automobile repair and maintenance

Wheel refurbishment: remove the oxidation layer of the wheel hub and restore the glossiness, with an efficiency 4 times higher than manual polishing.

Engine compartment cleaning: remove sludge and dust, no static adsorption, and reduce the risk of fire.

Cleaning and maintenance of Industrial Scouring Pads

1. Daily cleaning

Decontamination treatment: Rinse with clean water immediately after use to remove metal chips or dirt on the surface to avoid fiber clogging.

Dry storage: Hang in a ventilated place to avoid mildew caused by humid environment, and extend the storage life to 2 years.

2. Surface repair

Fiber regeneration: For slightly worn scouring pads, sandpaper can be used to polish the surface to restore friction.

Wire repair: Broken wires can be repaired by welding or replacing local areas to reduce overall replacement costs.

3. Long-term maintenance

Regular inspection: Check the fiber shedding after each batch of use, and replace it when the shedding rate is greater than 5%.

Environmental treatment: Waste scouring pads can be recycled to metal recycling stations or incineration power plants to reduce environmental pollution.